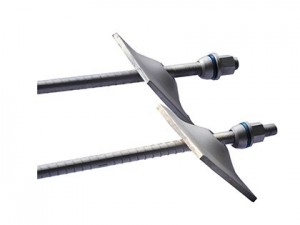

High duty, High strength wind turbine, wind energy tower foundation anchor bolt cage system in wind energy project. Components including anchor bolt(main part),flange, H.D. bolts, cap, leader bolt, concrete.

ADVANTAGE:

Excellent anti-delay fracture performance and long fatigue life(no damage after 12 million times test);

Provide double thread bolts with maximum length of 12000mm;

Standard: GB/T3098.1 ISO898-1 or costomer’s request

Mechanical Properties

| Grade | Dia | Tensile Strength Rm/MPa |

2% Elongation Limit RP 0.2/MPa |

Stress Under Proof Load SPf/MPa |

Elongation after fracture A/% |

Reduction oF Area after Fracture Z/% | Rockwell Hardness /HRC |

Bolt Length mm |

-40 ℃ Impact Absorb Energy K/J |

|

| min | max | max | ||||||||

| 8.8 | M16 ~M56 |

830 | 660 | 600 | 12 | 52 | 23 | 34 | 12000 | 27 |

| 9.8 | 900 | 720 | 650 | 10 | 48 | 28 | 37 | |||

| 10.9 | 1040 | 940 | 830 | 9 | 48 | 32 | 39 | |||

| 12.9 | 1220 | 1100 | 970 | 8 | 44 | 39 | 44 | |||

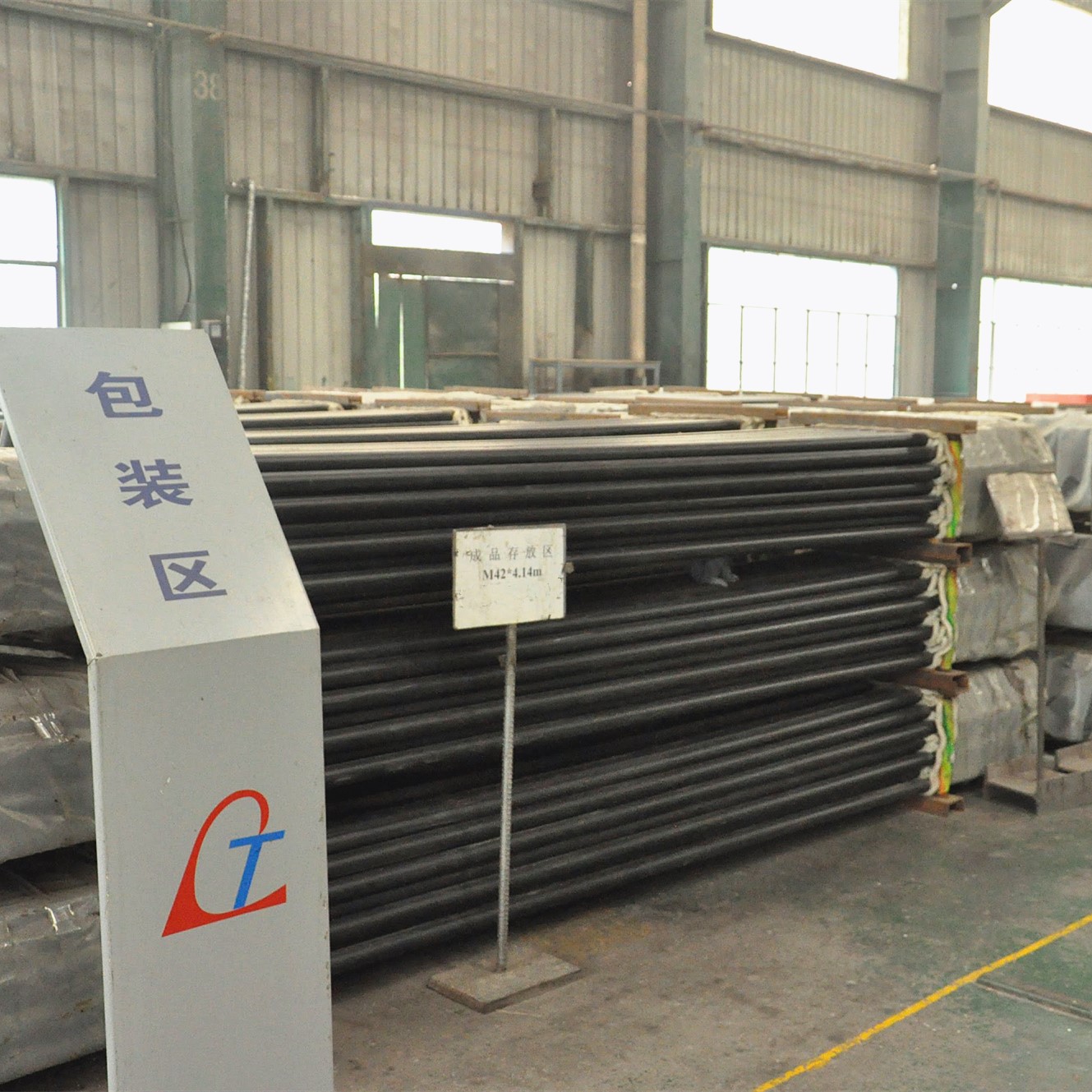

Common specifications

| DIA | Grade | Length | |

| Φ35mm(M36) | 8.8 | 10.9 | As Clients’ Demands |

| Φ40mm(M42) | 8.8 | 10.9 | |

| Φ45mm(M48) | 8.8 | 10.9 | |

| Φ53mm(M56) | 8.8 | 10.9 | |

Note: Grades, sizes are allowed to change

Manufacture Process

As per different raw materials and demands, process details will be adjusted.

Sample 1.

Raw Material Test — Normalizing — Sand blasting — Drawing & Straightening — Heat Treatment

— UT Test — Saw cutting — Chamfer — Polishing — Screw thread — Tensile test — Marking —

QC Test — Anti-corrosion Test — Stock

Sample 2.

Raw Material Test — Heat Treatment — Pealing — Polishing — UT Test — Saw Cutting — Chamfer

— Polishing — Screw Thread — Tensile Test — Marking — QC Test — Anti-corrosion Test — Stock

Process details information, please find at our BLOG within this website. Thank you!