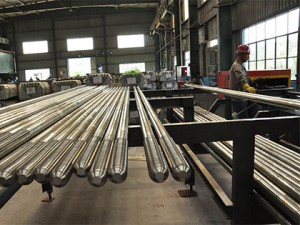

Thread rolling:

Thread of round bar is made by thread rolling machine, and it is measured by thread micrometer and through stop gauge to ensure thread size and precision to meet the technical requirements.

Thread rolling is the preferred method of producing strong, smooth, precise, uniform external threads. Rolling is different from other types of threading, such as cutting, grinding and chasing.

Thread rolling is a cold forging process that can be performed on any ductile metal. This forming process can be used to produce other special shapes such as knurling. In order to obtain the best quality threads, the process is carried out on precision uncentered blanks. The blank diameter of the rolled thread is at the pitch diameter and is the theoretical point between the large diameter and the small diameter.

The thread rolling company produces rolling threads for various parts. In general, rolling threads are required in the design due to the excellent tensile, shear and fatigue strength of the rolled threads. Other processes remove the material to create a thread form, but thread rolling replaces the material with a hardened steel mold. These molds typically have a hardness between Rc58-Rc63 and a specific set of dies for each thread size and each thread form.

The material particles are moved into the shape of the thread instead of being weakened by removing the material, with the result that the particles become denser at key parts of the thread, especially on the sides below the root and the pitch. This effect improves the quality of the thread form. Excellent surface treatment improves the assembly between the internal and external threads and reduces the wear between the mating parts, thus extending their service life. Another advantage of the rolled threaded assembly is that the surface is smooth compared to other threaded components.