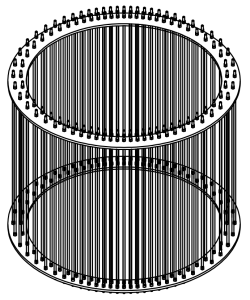

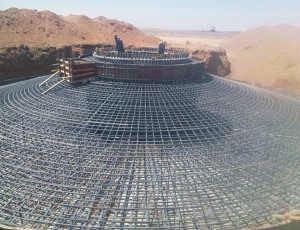

An Anchor cage is composed by anchor bolts, 2 anchor plates(templates)-upper template(temporary template, upper anchor bolt), lower template(lower anchor bolt), Steel Nuts, seal nut(nylon nut), Washers(gaskets), adjusting feet assemblies, splice plates(connecting plates), PVC tubes, corrosion protecting grease, fabric,HDPE bolt caps(bolt hat) etc

STANDARDS: GB/T 3098.1 ISO 898-1 OR AS CUSTOMER’S REQUIREMENTS

Anchor bolts are the most important part in this assemblies in WTGS(wind turbine generator system) since this part will bear the pre-stress, pre-tensioning forces, and take responsibility for the stability of the whole turbine or tower. Our manufacturer have the most advanced facility of heat-treatment of steel round bars, which means the pre-stress bearing capacity, tensile strength, yield strength abilities are much higher than the international standards. That is the reason why many world-wide companies choose us.

Mechanical Properties of Class 10.9 Bolt

| BOLT 10.9 | |||||

| D Nom | Diameter at smooth part | Pitch | Cross Section | Yield force | Ultimate force |

| mm | mm | mm | mm² | KN | KN |

| M36 | 33.23-33.29 | 4 | 817 | 768 | 735 |

| M39 | 36.23-36.29 | 4 | 976 | 917 | 878 |

| M42 | 38.90-38.96 | 4.5 | 1120 | 1052 | 1008 |

| M48 | 44.56-44.63 | 5 | 1400 | 1381 | 1528 |

| M56 | 52.22-52.30 | 5.5 | 2030 | 1908 | 2111 |

Diameter : M16~M56

Tensile strength, Rm of Grade 10.9: min 1040 MPa, 152ksi

Yield strength, RP0.2 of Grade 10.9: min 940 MPa, 138ksi

Stress under prrof load: 830 MPa

Elongation, A%: 10

Reduction rate, Z%: 50

Hardness: 32~39 HRC, 320~380 HV

Impact energy -40℃: 35J

Manufacture Process

Raw Material Test — Normalizing — Sand blasting — Drawing & Straightening — Heat Treatment

— UT Test — Saw cutting — Chamfer — Polishing — Screw thread — Tensile test — Marking —

QC Test — Anti-corrosion Test — Stock

Post time: Jul-15-2019