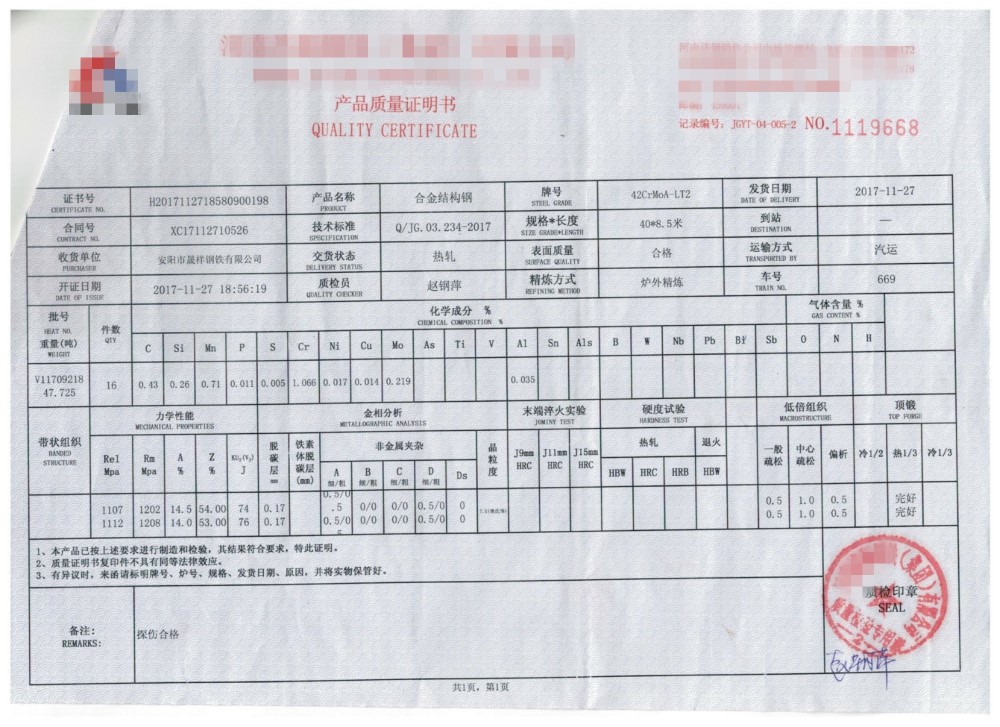

Our factory is top 5 Chinese wind turbine foundation cage manufacture in China. We cooperate with some of the worlds’ most famous wind turbine companies. Such as Gold Wind, Sany, Envision. It is reasonable that we have high reputation on quality among our clients. Our wind turbine foundation system products take the advanced technology in China. When we produce wind turbine foundation anchor cage, anchor bolt is one of the most important part. Before we produce anchor bolt, we need to purchase round bar as raw materials. grades are mostly 42CrMoA and 35CrMoA , also can have agreement with clients.

How do we choose prime quality raw material?

A. Chemical components

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 42CrMoA | 0.38-0.45 | 0.17-0.37 | 0.50-0.80 | ≤0.02 | ≤0.02 | 0.90-1.20 | 0.15-0.25 |

| 35CrMoA | 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | ≤0.02 | ≤0.02 | 0.80-1.10 | 0.15-0.25 |

Note:P+S content should not more than 0.03% Steel Round bars’ chemical composition tolerance should acc. to GB/T 222;

B. Nonmetallic inclusion

Measuring standard follows GB/T 10561, acc. to below graph:

| A(Selfide) | B(Aluminium Oxide) | C(Silicate) | D(Spherical Oxide) | Ds(Single ParticleSphere ) | ||||

| Thick | thin | Thick | thin | Thick | thin | Thick | thin | ≤2 |

| ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 | |

C. Macrostructure

The cross section macrostructure test piece of steel shall have no visible defects such as shrinkage holes, bubbles, cracks, inclusions, peeling, folding, and white spots, and general point-like segregation and edge point-like segregation are not allowed. Acc.to GB/T 226,GB/T 1979

| Center Porosity | General Porosity | Pattern Segregation |

| ≤2 | ≤2 | ≤2 |

D. Nondestructive Testing(NDT)

It is required that Steel mills should carry our 100% ultrasonic testing acc. to GB/T4162. Qualified UT level is Grade A

First Step after procurement and stock in.

Thread Rolling process

Contact us Now !

Post time: Jun-14-2018