5. Condition of delivery

5.1 Finished condition

The steel product shall be delivered in one or combination of the following finished conditions with or without heat treatment:

a) drawn, symbol +C;

b) turned, symbol +SH;

c) ground, symbol +SL;

d) polished, symbol +PL.

5.2 End condition

Unless otherwise agreed at the time of enquiry and order, the method of cutting shall be left at the discretion of the manufacturer.

Where specified at the time of enquiry and order, end conditions may be specified in accordance with A.2.

6 Tolerances on dimensions and shape

6.1 Tolerances on dimensions(diameter, thickness, width)

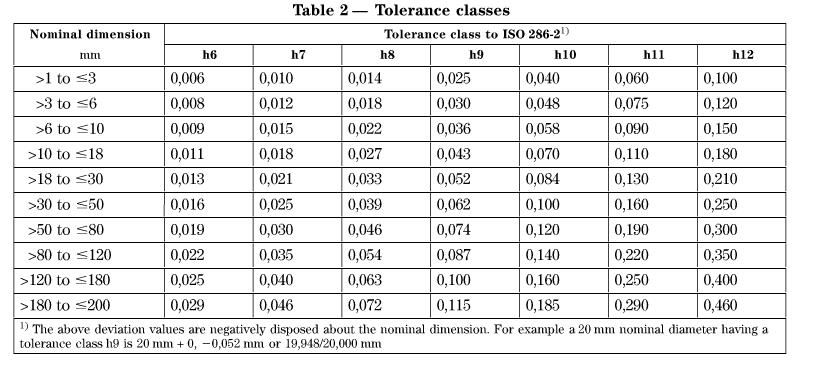

6.1.1 Tolerances on dimensions shall be specified by the purchaser at the time of inquiry and order and shall be in accordance with ISo 286-2 as set out in table 1.

6.1.2 Unless otherwise specified at the time of inquiry and order(see 6.3) tolerances on dimensions shall be as follows:

a) for drawn round bars, other than those under e), or turned bars: h10 to table 2;

b) for hexagon and square drawn bars: h11 for dimensions≤80mm, h12 for dimensions >80mm according to tables 1 and 2;

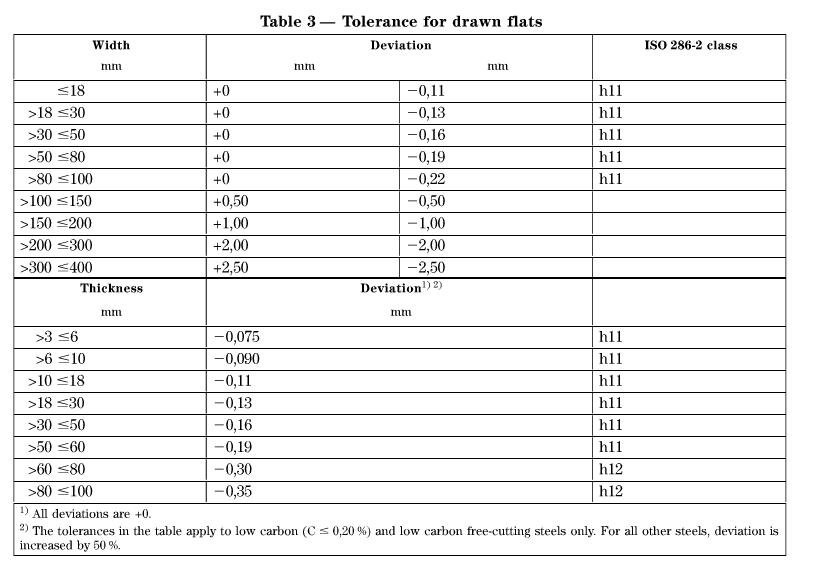

c) for drawn flats: in accordance with table 3;

d) for ground products: h9 in accordance with table 1 and 2;

e) for drawn round bars in the final quenched and tempered condition:h11.

6.1.3 WHere specified by the purchaser at the time of enquiry and order, the disposition tolerances specified in table 2 shall be in accordance with A.1.

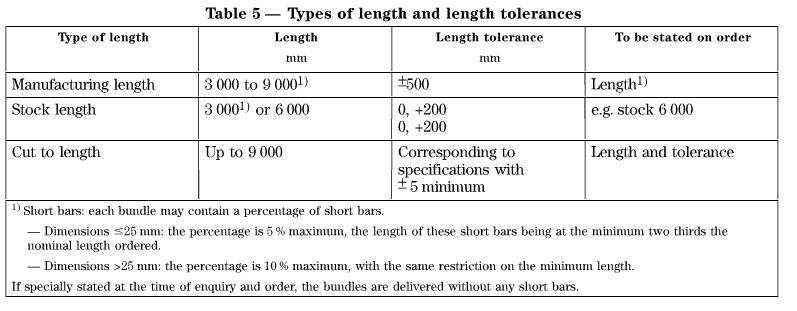

6.2 Types of length and length tolerances

Unless otherwise agreed at the time of inquiry and order, the length and the tolerance on length shall be as specified in table 5.

6.3 Out of round

Maximum deviation from “out of round” shall be not more than half the specified tolerance in any case never above the upper limit of the tolerance.

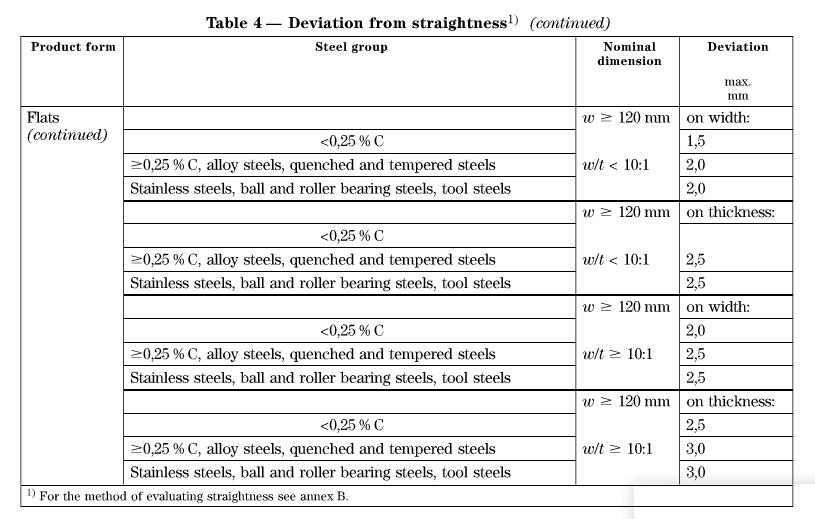

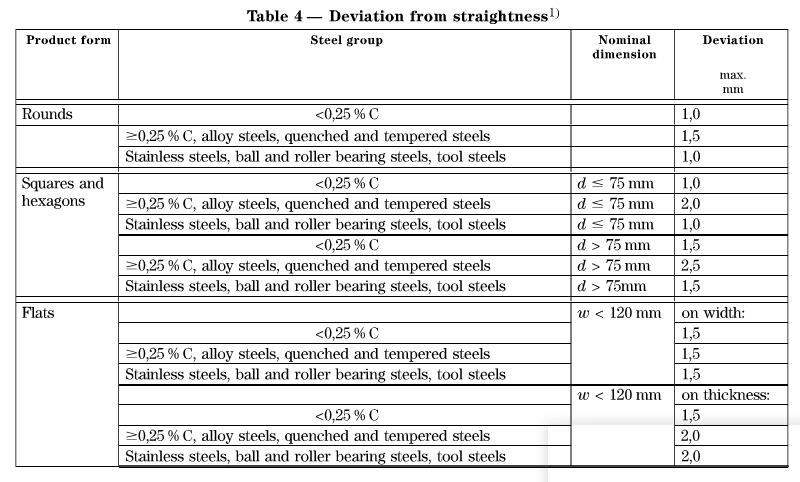

6.4 Straightness tolerance

Where specified at the time of enquiry and order and in cases of dispute, an agreed number of bars shall be evaluated for straightness in accordance with one of the methods specified in annex B and the tolerances specified in table 4 shall apply.

6.5 Edges of non-round bars

Non-round bars(i.e.square, hexagon and flat) in width ≤ 150mm may have an undefined profile within a distance of 0.2mm of the hypothetical edge, flats in width >150mm width a distance of 0.5mm, unless otherwise agreed. For width >150mm the corner profile may be underfined within a distance of 0.5mm of the hypothetical edge, unless sharp corners have specifically been ordered.

7 Inspection and testing

A sufficient number of samples shall be inspected for dimensional compliance.

Dimensional inspection shall be carried our as follows:

a) for round bars: not less than 150mm from the end of the bar;

b) for round bars cut to length: not less than 10 mm from the end of the bar;

c) for shapes other than round: not less than 25 mm from the end of the bar.

Post time: Oct-14-2019